Out-of-the-box innovation is essential as society shifts toward a greener and smarter future. With the rise of electric vehicles (EVs), and advancements in autonomous driving, automobiles are a major focus of this shift. It comes as no surprise that Japanese automakers, who produce approximately one-third of all vehicles worldwide, are at the forefront of vehicle innovation.

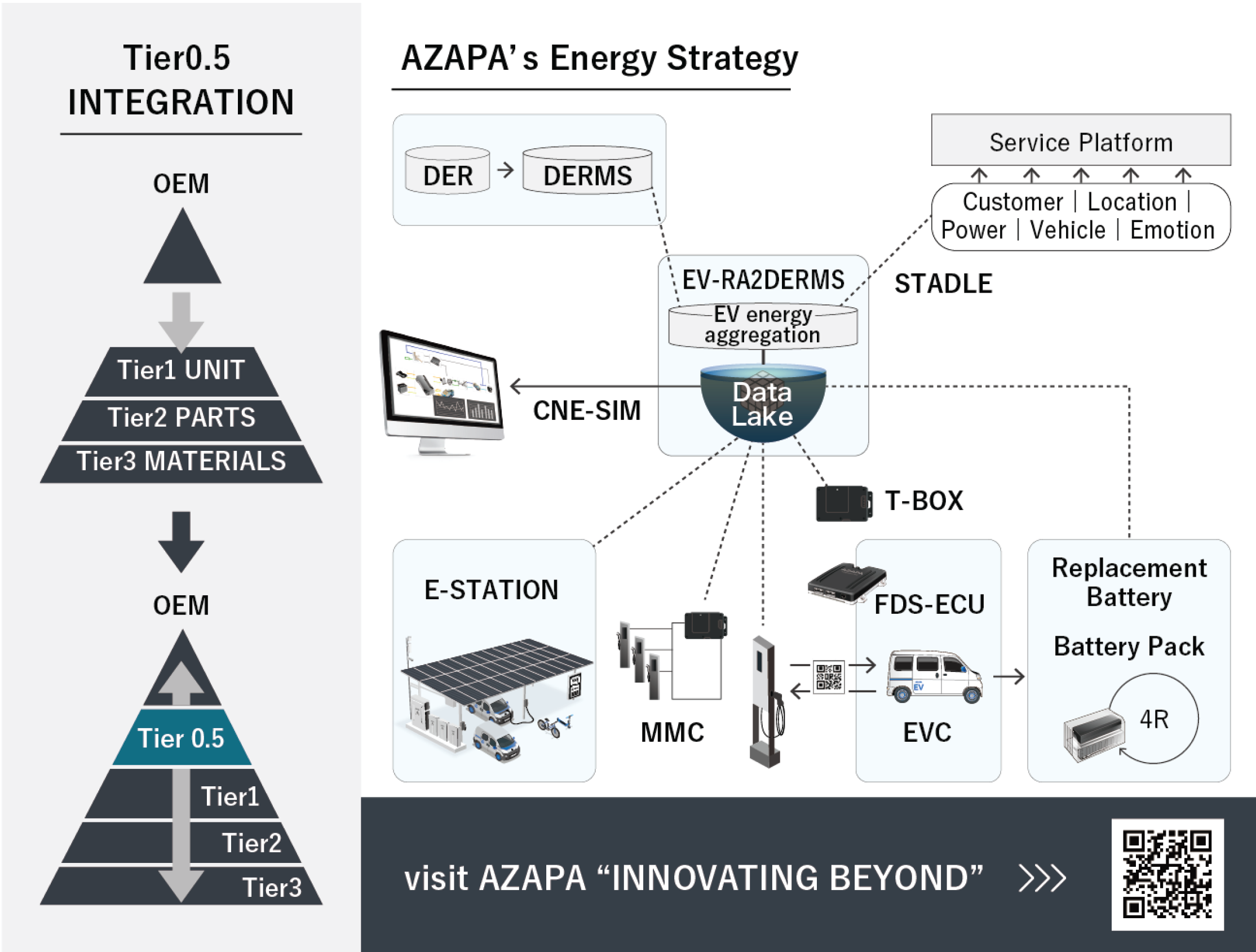

Yasuhiro Kondo began his career as a software engineer working on vehicle design, from engine controls to mass-production systems. In 2008, he assembled an all-star team of engineers to establish AZAPA, a dedicated technology startup. Since then, AZAPA has grown to become a domestic leader in designing automotive systems that balance functionality and performance. Based in Japan’s automotive heartland of Aichi prefecture, the company’s model-based development approach allows engineers to develop systems in virtual environments, saving time and costs. While leading this sector in Japan, AZAPA has expanded to bases in key technology hubs across China and the United States. Even as the company grows, “we remain like a venture, driving social implementation with agility”, said Kondo. AZAPA positions itself as a “Tier 0.5 ” firm—bridging technology developers and traditional suppliers. Drawing from an adept, creative talent pool, Kondo aims to inject new vitality into the car sector. “We are committed to optimizing the entire industry ecosystem, using our system-design technology,” he said. AZAPA’s strengths lie in vehicle pre-development, a crucial step in designing efficient solutions that create value for consumers. Recently, the company has looked to further couple the energy and mobility sectors. By treating vehicles and batteries as separate assets, AZAPA is looking to use its own blockchain technology to allow energy to be “traded” among locations in a secure fashion. In addition, its spinoff “Hakobune” project promotes investment in adjacent startups. “We need to leverage all of our accumulated expertise to create better solutions,” said Kondo. In the domestic realm, AZAPA has partnered with major Japanese electronics manufacturers and universities—collaborations Kondo views as essential for the industry’s future. While co-creation is often dismissed as a buzzword, AZAPA has seen tangible results from such initiatives. “We’re actively developing projects with academia, including new types of 3D printers,” Kondo explained. “Using these machines, we can combine hard and soft materials to create new products such as ergonomic chairs.”

Internationally, AZAPA continues to expand, working with overseas semi-solid-state battery makers and planning the construction of a manufacturing plant in Thailand. Kondo believes this will “boost the momentum of the global automotive industry, producing vehicles that truly meet the needs of each market.” Still, he remains committed to the strengths of Japan’s engineering culture. “Each country has its own specific character, based on available resources and culture built over time. In Japan, we thrive on unwavering quality. We need to take on a new role that integrates innovation from all over the world to tackle big challenges,” Kondo said.