It’s one of the biggest driving forces in today’s global economy—relying on the tiniest and most precise components for its successful manufacture. Semiconductors are vital for a wide range of industries and sectors, powering devices, circuits and all kinds of technology globally. That’s where companies like Athlete FA Corporation come in. The Japanese firm is a pioneering force in manufacturing components essential for the production of electronics.

As demand increases globally, the company’s precision research and development has been supporting the evolution of core technologies in the industry to help meet changing market needs. Athlete FA’s most significant product innovation is its solder ball mounter, crucial for all modern electronics manufacturing. Micro solder balls act as pathways for electrical signals on wafers and substrates used in semiconductor components. The firm has been helping shape the sector with significant advances in the field, and President Susumu Yamazaki takes his role in the tech industry very seriously. “The company’s core focus is the micro ball mounter that has been our top-selling product for the past few years,” said Yamazaki. “This machine plays a crucial role in smartphones, servers and computer components such as GPUs and CPUs by mounting solder balls to wafers and boards to create electrodes,” he said. One of the most critical elements of the company’s success in manufacturing electronic components has been keeping up with micro technology trends thanks to its expertise in miniaturization. As a result, it is working to reduce process sizes by as much as a third.

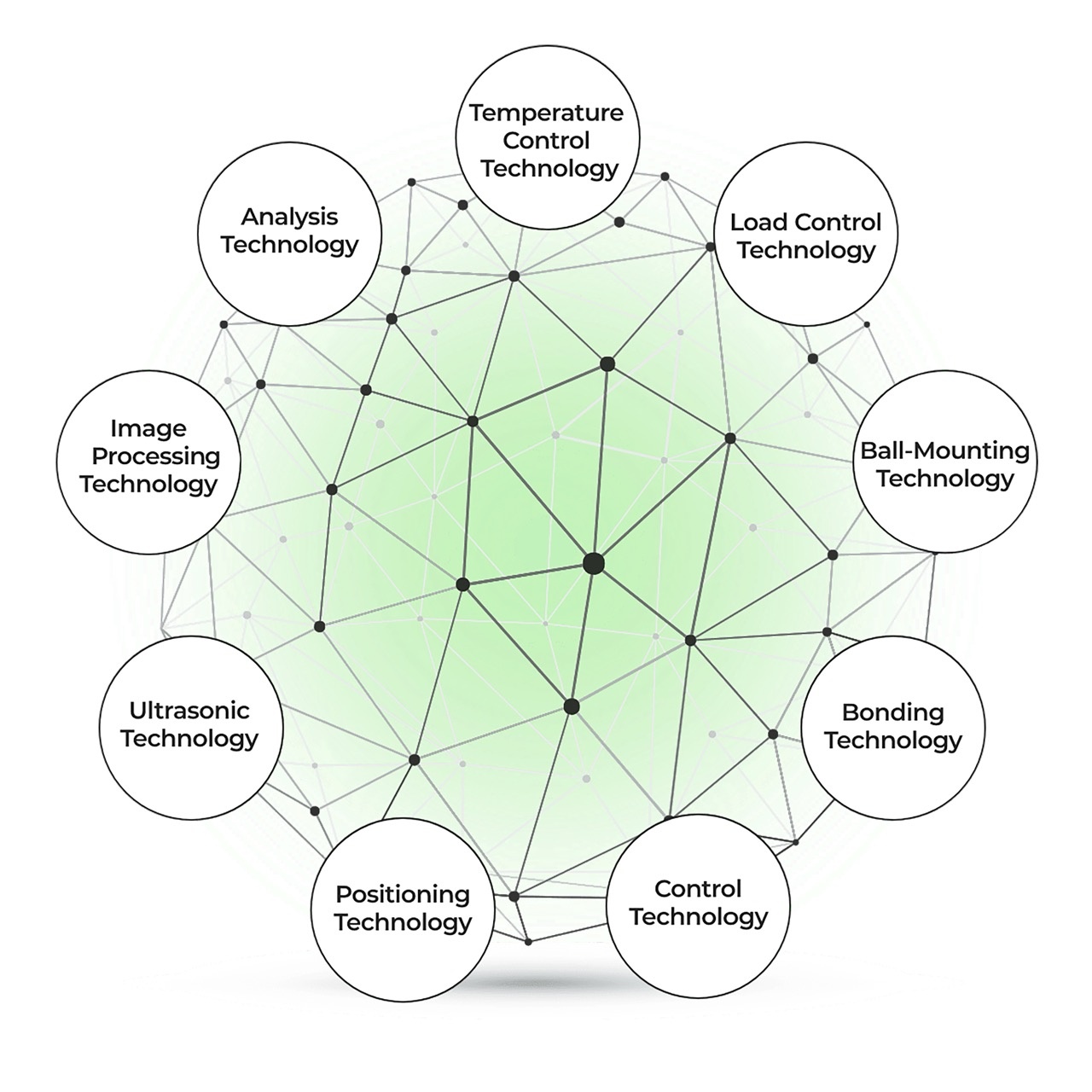

“As semiconductor chips continue to shrink, the size of solder balls has also decreased, with the smallest today being 45 microns. However, we have the capability to mount minute solder balls as small as 30 microns, ensuring precision and adaptability to the latest technological demands,” said Yamazaki. “We have been developing automation and assembly machines for electronic devices and expanding our portfolio into the semiconductor and LCD fields. Our company possesses the integral technology required for such equipment, giving us several competitive advantages,” he added.

Part of the firm’s growth strategy is to take advantage of Japanese government-backed plans to ramp up semiconductor manufacturing to better compete against rival nations, including South Korea and Taiwan. President Yamazaki believes his business’s greatest strengths are its ability to combine core mechanisms into affordable, high-quality products, and its agility in responding to changing conditions. He hopes the company can strengthen its overseas partnerships as a result.“These factors give us a significant competitive edge both within Japan and globally. Most Western companies have production facilities in China or Southeast Asia, so we aim to target the Western world as the next key region to introduce our core technologies,” said Yamazaki. “Our top-tier engineering and marketing capabilities allow us to swiftly understand and respond to client needs,” he added. Central to the firm’s successes has been a commitment to the Japanese business tradition of monozukuri, meaning to prioritize the best possible quality and customer service. “We have a strong commitment to monozukuri,a quality that has been very appealing to other nations for a long time. Japan has a long history of developing technology and is a world leader when it comes to the application of technology,” said Yamazaki.