Some names do more than identify—they embody a mission. For IEC Co., Ltd., a Japanese specialist in fluid transfer and supply systems, the principles of invention, evolution and creativity are the very origin of the company’s name. With over six decades of experience working with fluid materials, ranging from industrial paints and lubricants to resins, waxes and even sugar coatings for chewing gum, IEC’s business is based on delivering results to a diverse global client list across markets.

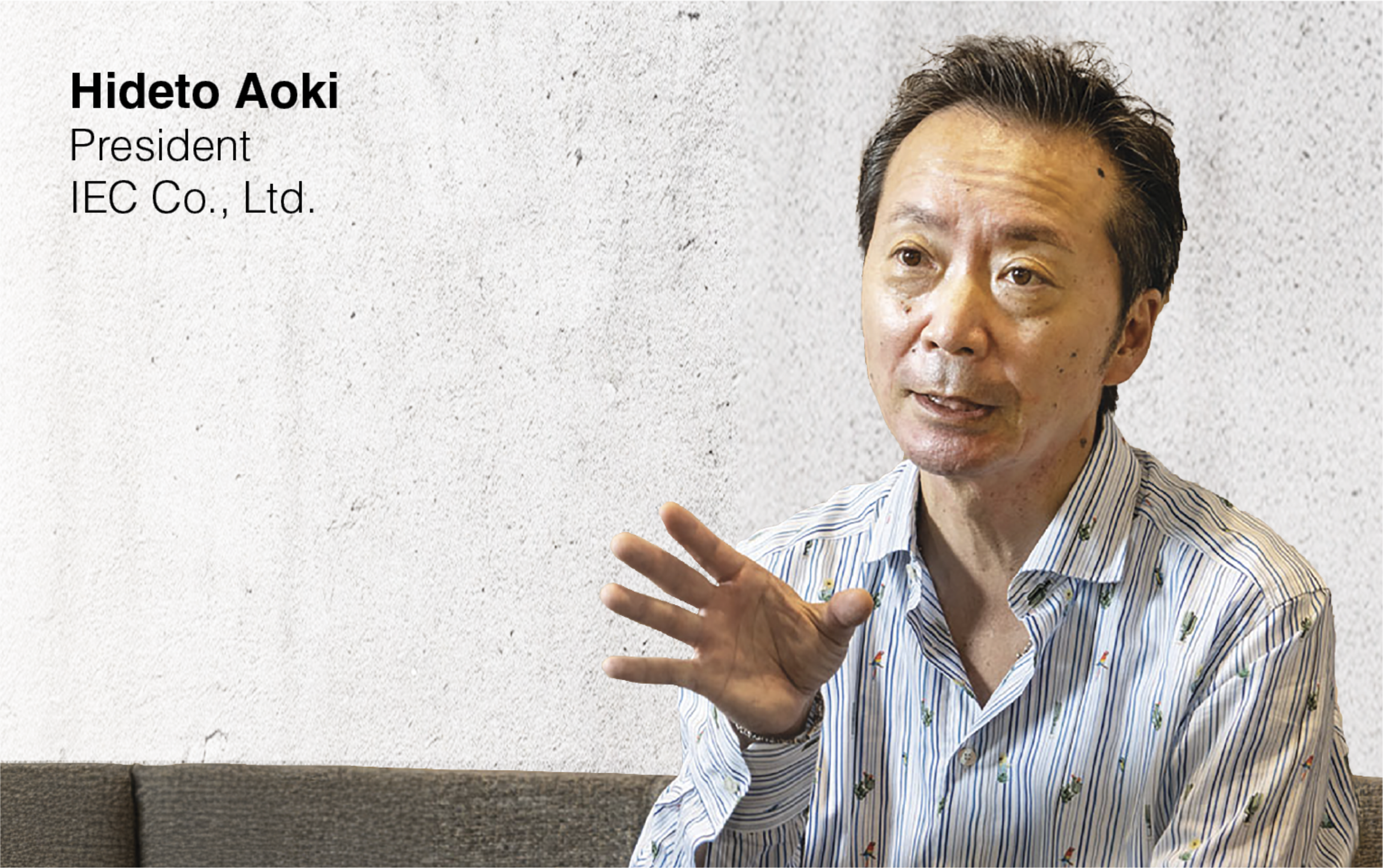

The company combines cutting-edge R&D with a commitment to long-lasting solutions, quality service and durability. IEC President Hideto Aoki believes it is crucial that customers know they can depend on his firm. “As we have done for decades, our company will always stand by our clients’ side and see the job through to completion,” said Aoki. “Unlike other companies that tend to give up once they feel it is no longer possible to succeed, we will always strive to make sure the result is positive,” he added. A hallmark of the firm’s success has always been the diverse applications of its products and systems. IEC has adapted fluid delivery technologies for spray painting large structures such as bridges and seagoing vessels. In areas of micron-level precision, IEC’s fluid supply systems work at smaller scales to help apply grease and silicon for electronic components processing. Across Japan, IEC helps to deliver precision in niche, behind-the-scenes areas, where a pause in production can cost clients precious time and resources. These include dispensing sugar coatings for medical tablets, mixing ingredients used in cosmetics production, and applying adhesives for manufacturing household appliances, including LED displays.

To help maintain its innovative edge, IEC engages in partnerships with a broad spectrum of stakeholders. Recently, the firm has been working on joint projects with e-commerce giant Amazon to supply automation equipment for its fulfillment plants. “We set up a technical center and laboratory as a platform to demonstrate our expertise. It is our co-creation environment where we can collaborate with cherished clients and extend ideas that lead to joint projects,” Aoki said.

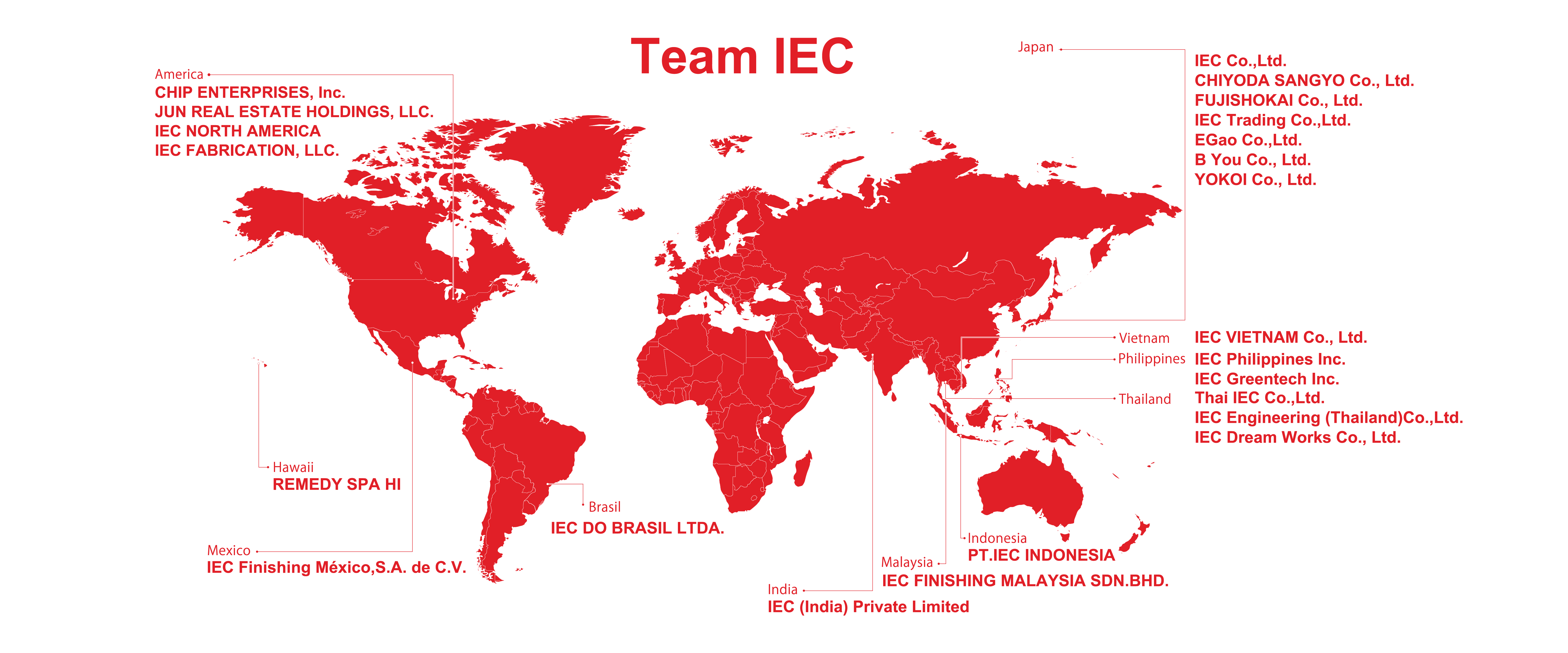

Founded in Nagoya in 1960, IEC’s success story has spread far beyond Japan’s borders over the last 65 years. IEC has a growing presence across several continents, with bases in the United States, Mexico, Brazil, India and Southeast Asia. The firm hopes its next expansion will be in Europe, following an exclusive deal agreed upon with the U.K. brand Bamford Cosmetics. Part of IEC’s corporate strategy to develop its global outlook includes offering global experiences to its staff. President Aoki is particularly keen to promote exchanges and visits provided throughout the company. “The next two to three years, I want to encourage my younger employees to venture abroad to our bases in India, Vietnam, Brazil and Mexico, so that they can broaden their perspectives,” said Aoki.

Looking ahead, the firm is targeting the growing electric vehicle market, alongside some even more stellar product goals. “Most demands are coming from the EV battery field. So far, our expertise has been well received from stakeholders in the auto industry, and we have received praise for our fluid handling and coating technology,” said Aoki. “An overarching theme of our R&D is going to outer space. I made a promise in front of all our employees—there is unlimited potential for our expertise when it comes to cosmic endeavors, and that is our ultimate goal,” he added.

Organic matter magnetic pyrolysis energy conversion device MG22Eh®.

Last but not least, IEC is committed to supporting the Sustainable Development Goals (SDGs). Aoki said that the business is working through a ten-year strategy that includes diversifying into new businesses such as restaurants, with targets to reduce emissions and energy use. The project also includes introducing a magnetic pyrolysis energy conversion device, MG22Eh®, which thermally decomposes organic waste—instead of incinerating it—using the plasma effect from magnetism and harnessing the heat from further decomposition to produce steam and electricity. “Those non-manufacturing businesses are the second pillar of our business now—energy saving initiatives will never reach zero, so instead we must make better use of resources. This is why we have the two pillars working in parallel,” said Aoki. He adds, “We must prioritize our sustainability pillar to ensure that IEC will survive in a business setting.”